Cornell CUP Robotics

Cornell CUP Robotics is a team of 60 students working on several different robotics projects. My work has been on C1C0, a R2-D2 inspired lab assistant robot. I have undertaken several projects on the team, including a lens aperture for the facial recognition camera and the end effector for the precision arm.

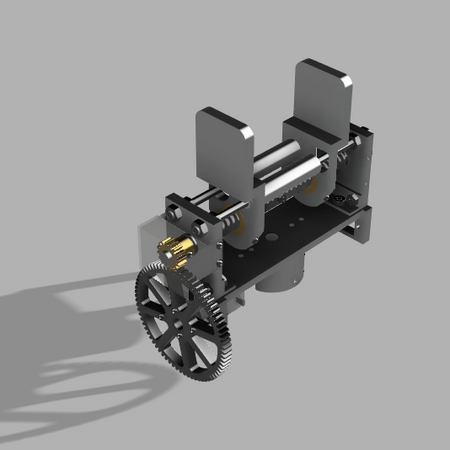

Precision Arm End Effector

The precision arm end effector is a manipulator designed to hold objects up to 70mm in length and weighing up to 4 lbs. The main driving mechanism consists of two lead screws of opposite thread direction placed end to end and secured with a half-lap joint, which allows the end effector to be powered by a single micro servo. By using opposite threads on each side of the end effector, the fingers are able to move in opposite directions at the same time, creating the opening and closing motion. The lead screws were chosen as the optimal design as they ensure that the distance the fingers move is always proportional to the number of rotations of the micro servo with minimal slippage, and the purely linear motion ensured that the distance from the point where the end effector attaches to the rest of the precision arm to the tip of the fingers was constant, which simplifies the algorithms the software team is developing to allow C1C0 to interact autonomously with objects. Due to the small size of the end effector, I had to learn to operate the team's CNC mill to manufacture many of the parts. Future plans for the end effector include designing silicone pads for the fingers to both increase friction and thus grip strength and to house a pressure sensor to provide feedback about whether or not an object has been successfully grasped.

Lens Aperture

The lens aperture is designed to both protect the facial recognition camera and act as an aesthetic "eye" for C1C0, similar to the radar eye present on R2D2 and the other astro mech droids in the Star Wars saga. The lens aperture consists of 12 thin, 3D-printed leaves with pegs that insert into holes in a large ring gear. The leaves also have pegs on the opposite side, which run along tracks in a circular base. The tracks cut straight through the base creating "pie wedges", which allow the leaves to open and close as the ring gear rotates. The mechanism is driven by a singular gear attached to a micro servo.

Shell

The shell consists of thin pieces of polystyrene designed to provide an aesthetic appearance similar to that of the astro mech droids from the Star Wars saga. The "head" of the robot consists of a 20 inch diameter hemisphere, with cutouts for the various electronics present in the head such as the facial recognition camera, path planning camera, microphones, speaker, and tablet. It also contains several areas of small holes in a mesh-like pattern, to allow for airflow through the head to prevent the electronics from overheating without impacting the aesthetic design. I also designed a concept model for the body of the shell assuming the shell should be as solid as possible to prevent dust and debris from accumulating within the structure of the robot. Unfortunately, the files for this design have since been lost. For later revisions, this portion of the design was handed off to another group of students and redesigned for more aesthetic appeal.

Vacuum Former

The original manufacturing plan for the shell involved vacuum forming polystyrene panels to the desired shape, similar to how many professional props are manufactured. The goal was to be able to manufacture all the parts in house, so I was tasked with designing and building a prototype vacuum forming machine. The base of the machine consisted of a hollow box constructed from two by fours with a sheet of plywood on the bottom, and a sheet of pegboard for the work surface, and was to be powered by two commercial shop vacuums connected to opposite sides of the box. The box was sealed with silicone caulk to make it airtight except for the desired holes on the worksurface, and the holes to connect the vacuums. A second team of students was tasked with designing a rig to evenly heat the plastic sheets and safely lower them over the forms. This project was scrapped after subsequent tests proved that the volume and strength of the vacuum required to successfully form pieces of the necessary size was much more than could be maintained by a commercial shop vacuum, and to upgrade the vacuum would have been outside our budget.

Project Gallery